In industrial settings, ensuring worker safety and maintaining compliance with regulations are top priorities. One of the most critical aspects of workplace safety is detecting hazardous gases that may be present in the environment. Gas leaks can pose significant threats, ranging from health risks to potential explosions. This is where industrial gas detection in the UK plays a crucial role.

The Importance of Industrial Gas Detection in the UK

Industries such as oil and gas, manufacturing, mining, and chemical processing operate in environments where hazardous gases are a constant risk. Detecting these gases in real-time is essential to prevent accidents, protect personnel, and comply with health and safety regulations. The Health and Safety Executive (HSE) in the UK has strict guidelines for gas detection and monitoring in workplaces.

Common Gases Monitored in Industrial Settings

Some of the most commonly monitored gases include:

Carbon Monoxide (CO): A colorless, odorless gas that can be fatal when inhaled in high concentrations.

Hydrogen Sulfide (H2S): A toxic gas often found in wastewater treatment plants and oil refineries.

Methane (CH4): A highly flammable gas that can cause explosions if not properly monitored.

Oxygen (O2) Levels: Monitoring oxygen levels is crucial in confined spaces to prevent asphyxiation hazards.

Volatile Organic Compounds (VOCs): Common in industries dealing with paints, solvents, and chemicals.

Advanced Gas Detection Technologies

Modern industrial gas detection UK solutions include advanced sensors and automated systems that continuously monitor gas levels in real time. These systems provide immediate alerts when gas levels exceed safe limits, allowing for quick intervention. Some of the technologies used include:

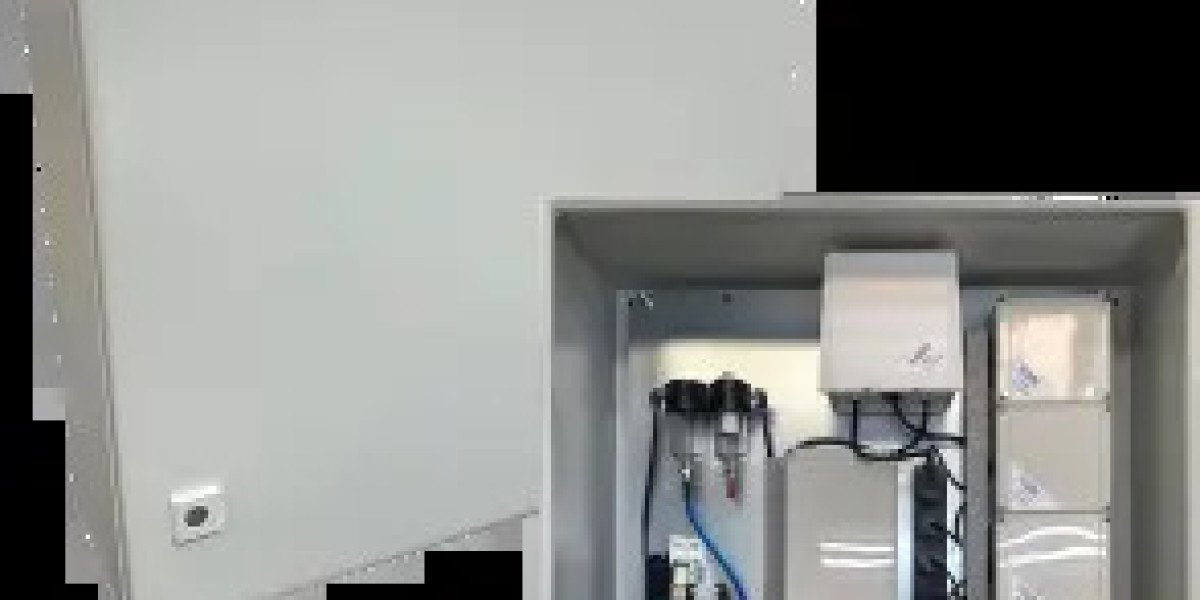

Fixed Gas Detection Systems: Installed in specific areas where gas leaks are likely to occur.

Portable Gas Detectors: Handheld devices used by workers to assess gas levels in different locations.

Wireless Monitoring Systems: These provide remote monitoring capabilities, ensuring a swift response to potential leaks.

Single Line Sampling Systems: A Reliable Gas Detection Method

Among the various gas detection technologies available, Single Line Sampling Systems have emerged as a reliable and efficient solution for industrial applications. These systems offer a streamlined approach to monitoring multiple locations from a single point, making them ideal for environments where continuous gas sampling is required.

How Single Line Sampling Systems Work

Single Line Sampling Systems function by drawing air or gas samples from multiple locations through a single sampling line. The collected sample is then analyzed to detect the presence of hazardous gases. These systems are particularly beneficial in:

Confined Spaces: Ensuring safety in areas with limited ventilation.

Remote Locations: Reducing the need for manual monitoring.

High-Risk Environments: Detecting toxic or explosive gases in critical industrial settings.

Key Benefits of Single Line Sampling Systems

Cost-Effective: Reduces the need for multiple detectors, minimizing installation and maintenance costs.

Accurate Monitoring: Provides consistent and precise gas detection results.

Customizable Solutions: Can be tailored to specific industrial needs.

Reduced False Alarms: Advanced technology ensures reliable gas detection with minimal false readings.

Enhanced Worker Safety: Allows early detection of hazardous gases, preventing potential risks.

Choosing the Right Gas Detection and Sampling System

When selecting a gas detection solution, industries should consider factors such as:

Type of Gases Present: Different sensors are required for various gases.

Environmental Conditions: Harsh conditions may require rugged, weather-resistant equipment.

Regulatory Compliance: Ensure the system meets UK safety standards.

Ease of Maintenance: Opt for systems that require minimal upkeep.

Conclusion

Both industrial gas detection UK solutions and Single Line Sampling Systems are essential for ensuring workplace safety. As industries continue to evolve, investing in advanced gas monitoring technologies is crucial to maintaining a safe working environment. Companies like Comteck Solutions provide state-of-the-art gas detection systems tailored to the unique needs of various industries, helping businesses enhance safety and comply with regulatory requirements.

By integrating modern gas detection solutions, industries can proactively manage gas hazards, protect workers, and ensure operational efficiency. Stay ahead of safety challenges by adopting the latest gas monitoring technologies today!